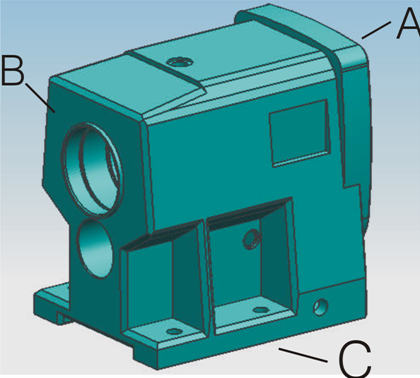

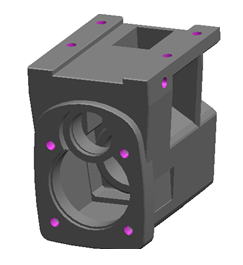

Thehousing is an important component of the motor. It is the base of thetransmission parts, and it should have enough strength and rigidity.

Thecase is usually made of gray iron, which has good casting performance and vibrationdamping characteristic. Cast steel case is also applied for reducer with heavyload or impact load.

Machiningprocess:

Rough millingsurface A – Rough and finish milling surface C (bottom surface)—Rough millingsurface B—finish milling surface A,B—Rough boring-Groove milling—finish boring——Drilling--Tapping

Facemilling

Tool:FMD02-080-A27-PN11-08

Cutting data:Vc=200m/min,fz=0.2mm/z,ap=2-5mm

☆Inserts with wiper ensure stablesurface quality at different cutting depths.

☆Most suitable for cast ironmachining, especially automotive cylinder block milling.

☆ Maximum cutting depth can be up to15 mm. When cutting depth is greater than4 mm, it is best for machine too to be above10 KWH. When machine power is not enough, please select the light load geometryand coarse teeth structure.

Grooving

Tool:SMP05-039X3.0-XP25-QC16-03

Cutting data:Vc=150m/min,fz=0.15mm/z

☆ Two types of insert head: round and square.3 effective cutting edges for each insert.

☆ Insert vertically mounted. Same insert canbe applied for external and internal turning tool holder and groove millingtool holder.

☆ Widely applied in shallow groove and groovemilling for various shaft and ring parts in machinery industry, especially drivingmedium, connecting rods of motor and engine industry.

Largehole making

Rough boring

Tool: new type rough boring cutter with adjustable device

Insert:YBD152/CCMT09T304-HM

Cutting data:Vc=

Boring: Finish boring

Tool: new type finish boringcutter

Insert:YNG151/TBGH

Cutting data:Vc=

Chamfering

Tool:CMA01-032-XP32-SP12-03

Insert:YBG302/SPMT120408

Cutting data:Vc=

Smallhole making

Drilling

Tool:SUseries drill

Cutting data:Vc=50

☆ Wide application in high efficiency machining in various materialse.g. P-, M-, K-, S-(heat resistant alloy), etc.

☆ Optimized geometry and wavy edge for outstandingsharpness and strength and smooth chip evacuation.

☆ 140 point angle reduce feeding force in initialphase of drilling operation, guarantee excellent self-positioning capabilityand increase hole machining quality.

Tapping

Tap

Cutting dataCutting data:Vc=