Laptop shell is a critical part for protecting laptop itself, also affects the heat-dissipation effect, weight and aesthetic perception. The common materials of laptop shell include alloy and plastic, etc. Alloy shell includes aluminum alloy and titanium alloy, plastic shell includes carbon fiber, PC-GF-*(poly carbonate) and ABS engine plastic, etc.

Aluminum magnesium alloy: aluminum is the main element in aluminum magnesium alloy, mixed with a small quantity of magnesium or other metallic materials to reinforce its strength. Because it is metal, the heat-conductivity property and strength are particular outstanding. With strong rigidity and light weight, low density,good heat-dissipation, strong pressure-resistance, aluminum magnesium alloy can well meet the demands of 3C products (computer, communication and consumers electronics) highly integration, light-weight, micro miniaturization, resistance to fall and hit, electromagnetic shielding, heat-dissipation. The hardness of aluminum magnesium alloy is several times of plastic shell, but the weight is only one third of the plastic shell, due to the merit, it is often made into ultra-thin or small dimension shell of middle and high class laptop. Thus, aluminum magnesium alloy is the first choice of laptop shell material. At present, the majority of laptop manufacturers use aluminum magnesium alloy as material. Disadvantages:aluminum magnesium alloy is of low strength and wear-resisting, higher cost,expensive, also more complex and more difficult processing techniques (punching press or die-casting is needed) than ABS, it is rare to see that whole lap to shell are made from aluminum magnesium alloy.

Nextis the introduction of ZCCCT tools application in aluminum magnesium alloy keyboard frame.

Laptop keyboard frame machining process: casting, cutting, machining on upper surface,machining on upper and lower bottom cavity.

◆ millingon upper surface

workpiece dimension: 350 mm×240 mm×15 mm

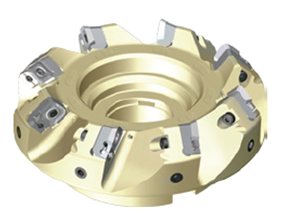

Tool: AMA01-100-A32-SE12-06C

Insert: YD201/SEHT12T3AFFN-AL

Cutting data: Vc=2000 m/min, fz=0.1 mm/z, ap=1mm, ae=55 mm

Cooling style:air cooling

Results: YD201/SEHT12T3AFFN-A Llifetime is 100 pieces/edge in stable working condition, without deformation after machining,after machining 100 pieces per edge by applying similar product of company A, generate edge chipping work piece deformation.

Insert wear comparison after machining 100 pieces

ZCC·CT (edge in god condition) Similar product of company A (Edge chipping)

Machining on upper and lower bottom cavity.

Roughing

Tool:AL-3W-D20.0

Unique wave edge design, excellent chip breaking performance, can effective lower cutting force during operation, improve cutting condition, this tool is suitable for high-efficiency aluminum alloy roughing.

Cutting data

n=5000r/min f=

ap=

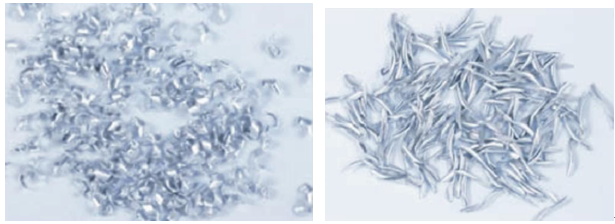

AL-3W-D20.0 chips solid carbide endmill chips

◇ semi-finishing

Sharp edge and large helical angle design, lower the probability of build-up edge, anti-vibration design, effectively curb vibration during operation, even in groove and cavity machining still demonstrate excellent performance.

Tool: AL-3E-D16.0

Cutting data: n=5000r/min

f=

ap=

ae=

Tool option 1: AL-3E-D4.0

Cutting data: n=10000 r/min

f=2000 mm/min

ap=0.5 mm

ae=1 mm

Tooloption: 2AL-2B-R1.0

Cutting data: n=20000 r/min

f=2000 mm/min

ap=0.1mm

ae=0.2mm

High precision edge design, is most suitable for high precision profile milling of aluminum alloy.

For more productive, innovation-oriented and highly effective cutting products and solutions, Please contact one of our engineers and check our ZCCCT products catalogs.