New Interchangeable cutter head modular endmills series, integrates the advantages of solid carbide tools and indexable tools for high-precision, high rigidity and high efficiency

Solid carbide cutter head, with high precision and good consistency.

Self-centering tapered thread coupling, with quick and easy set up and tool changes, high security and reliability , high strength.

Double-locating inaxial and radial directions, with good stability and high mounting precision.

Quicktool head change in machine shortens the supporting time and improves production efficiency.

Three cutter head series, shared a tool holder with indexable interchangeable series can well meet the demands ranging from roughing to finishing operations in face milling, slot milling, square milling, profile milling, ramping, helical interpolation.

Interchangeable cutter head modular

Interchangeable cutter head: flattened, ball-nose and R types

Thread curve surface contact with high precision, good precision and stability

Locating surface with high precision

Ensuring perfect combination between tool holder and tool head

Interchangeable cutter head

There are steel tool holder, welding tool holder, solid carbide tool holder to choose from, they are suitable for various operations with large overhang and high feed rate.

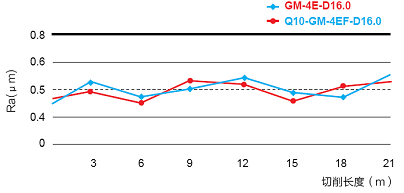

Work piece material: 42CrMo(HRC35)

Milling style: Side milling

Tool head: Q10-GM-4EF-D16.0

Tool holder: G16-QCH-Q10-120S

Cutting modes: Down milling in wet-type

Machine: Vertical machining center

Cutting data: Vc=

Results:New interchangeable cutter head modular endmills, with high precision and good surface quality, consist with solid carbide endmills.

Good rigidity and longer tool life

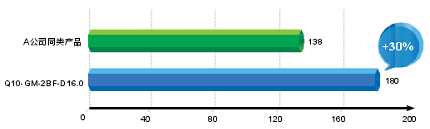

Work piece material: NAK80 (HRC40)

Milling style: Profiling

Tool: Q10-GM-2BF-D16.0

Tool holder: G16-QCH-Q10

Cutting modes: Down milling in wet-type

Machining requirement: Ra≤0.6μm,When Ra>0.6μm, Invalid

Machine: Vertical machining center

Cutting data: Vc=

Results: interchangeable cutter head modular endmills with good rigidity and excellent vibration resistance,compared with similar product from company A, it enjoys longer tool life and higher efficiency.